Gibraltar WaterSupply History

Moorish

Period

The first efforts to provide a water supply system for Gibraltar are traced to the Moorish occupation. Several wells have been identified as having been constructed in that period. Particularly there was an artificial well/reservoir, now known as Nuns Well, which comprised an underground arched chamber into which ground water was allowed to drain for eventual use.

The Moors also constructed an aqueduct, which led water from wells to the Moorish Baths at Line Wall. It is also interesting to note that the Tower of Homage at the Moorish Castle incorporated a shaft like reservoir into which rainwater from the roof was channelled for storage and use.

Spanish

Period

Apart from constructing some more wells, (ie there was a Noria Well near the Alameda) the Spaniards constructed an aqueduct in 1571, following on part of the route of the Moorish one, to convey water from Rosia Road to Fountain Ramp at the town centre. The works, engineered by a Jesuit under the patronage of the Conde de la Corsana, comprised two underground reservoirs one of 68 cubic metres and the other of 38 cubic metres capacity at Rosia Road, receiving rain water and ground water percolating from the Alameda sands.

Works were extended in 1694 by a third reservoir holding 35 cubic metres at Rosia Road and a fountain incorporating a 50 cubic metres overflow reservoir at the town centre. The face of this fountain can presently be seen set against the fortification walls at the Boulevard near the Community Centre. The aqueduct has a length of some 1,220 metres and consists of arched galleries with entrances via eight shafts. Only one shaft is currently visible at Rosia Road.

Pre Sanitary

Commissioners

After the capture of Gibraltar in 1704 there was no public water supply as such. The military looked after their needs as best they could and the population fended for themselves generally using the old Spanish aqueduct/fountain and wells of brackish water. As the population and strength of the garrison increased, it was sheer necessity which dictated that underground tanks, collecting rain water from roofs, should be incorporated in the construction of barracks and dwellings, around 1853. By 1863 there were 136 dwellings with underground tanks catering for the needs of 4,497 persons for ten months in the year at 6.75 litres per head per day. A further 179 houses inhabited by 2,775 persons used 6.75 litres per head per day derived from the old Spanish fountain in the centre of town and from wells in the North Front area. This water was conveyed from source to the houses in barrels or buckets. A further 133 houses used by 2,320 persons had wells yielding 4.5 litres per head per day of brackish water. Matters were made worse when many of the private wells were closed down in an effort to stem the cholera epidemic and the use of the Spanish aqueduct was discontinued for Public Health reasons.

In 1863 a Parliamentary Commission on Barrack and Hospital Improvement enquired into the sanitary conditions and improvements of Mediterranean stations. In evidence given to the Commission the Garrison Quarter Master had the following to say

“The inhabitants (of Gibraltar) owe nothing to the British Government for the small supply of water they have had for 150 years”.

— Garrison Quarter Master

The Commission reported that it was hardly too much to say that there was not a water pipe in the whole Town except for the old aqueduct. They also made proposals for the preparation of an area of rock above the Moorish Castle area as a catchment area for rainwater. The vegetation was stripped and the rock so exposed rendered impervious by filling in cracks with cement sand mortar. The water so derived was to be conveyed into a large 5,682 cubic metres reservoir constructed of masonry and concrete.

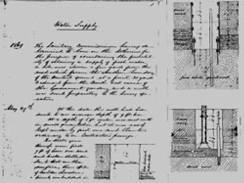

Following the Report of the Parliamentary Commission, the Sanitary Commissioners to Gibraltar were set up and entrusted with the task of laying on a piped water supply to the Community. The Sanitary Commissioners provided the foundations to the present water supply system. In 1869 the first Public Health Ordinance was published wherein it was made mandatory for underground tanks to be provided for any new dwellings to be constructed. Even today our Public Health Ordinance requires that new dwellings, in areas where potable water is not available from the Public Water Supply network, must be provided with underground tanks. This law, however, has limited application today since most development areas are within a reasonable distance from our water mains.

In 1869 ground water exploration was initiated by Mr E Roberts, Engineer to the Sanitary Commissioners. A sandy aquifer was found at the isthmus, which links Gibraltar to Spain. Wells were constructed and a pump house and pumping system built to convey this water to public reservoirs at Moorish Castle and Europa Road areas. The water from these wells became brackish very quickly and was used mainly for sanitary purposes; the water collected from rains being used for dietetic purposes. From this developed our unique system of dual water supplies whereby there are two supply and distribution systems; one for potable water and the other for seawater. Seawater is used for fire-fighting, street flushing, sewer flushing and other sanitary purposes where the use of potable water is not essential. Every house enjoys a supply of salt water paid for under the “Rates” and a supply of potable water that is metered and billed for on a monthly basis. This dual supply system reduces the amount of potable water required by over fifty percent. It is interesting to note that water,

from the condensers of steam machinery used to lift seawater to various reservoirs, provided some 45.5 cubic metres of distilled water per annum in the late 1800’s and was the first attempt in Gibraltar to produce fresh water from the sea.

The Commission reported that it was hardly too much to say that there was not a water pipe in the whole Town except for the old aqueduct. They also made proposals for the preparation of an area of rock above the Moorish Castle area as a catchment area for rainwater. The vegetation was stripped and the rock so exposed rendered impervious by filling in cracks with cement sand mortar. The water so derived was to be conveyed into a large 5,682 cubic metres reservoir constructed of masonry and concrete.

Pre Sanitary

Commissioners

The inception of the “Waterworks” as they stand today took place between 1898-1900. In this period four reservoirs, each being 60.96 metres long 15.24 metres high and with an average width of 6.1 metres, with a total capacity of 22,727 cubic metres, were excavated from the solid rock in the west side of the Rock at an elevation of 103.6 metres above sea level. The excavations were lined with bricks and rendered impervious. These reservoirs were fed with water collected from a rocky area, on the north west upper slopes of the Rock, cleared from its natural vegetation and all crevices filled with concrete. The water thus collected was conveyed through open channels and pipes into the reservoirs.

As the populations and demand for water increased, further sources of supply were required and a further scheme was proposed and carried out. This consisted of:

(a) forming a catchment area of some 40,000 m2 hectares on the east side of the Rock; and

(b) driving a tunnel, 800 metres long from east to west, in which was formed a channel to convey the water to the existing reservoirs on the west side. This was the start of a system, which is unique in the world and is an engineering achievement of considerable merit.

Catchment

The first catchment area of this type (an entirely original idea conceived by the then City Engineer of Gibraltar) was constructed in 1903 on the sand slopes of the east side of the Rock, which has an average inclination of 1½ to 1. These slopes had big boulders embedded in them, which were blasted away, the surface trimmed as even as possible and a channel and footpath constructed at the lower perimeter of the collecting area. Into these trimmed sand slopes timber piles 1500mm x 150mm x 40mm were driven their full length, to these a timber framing of 75mm x 75mm x 4500mm purlins and 75mm x 75mm x 2400mm rafters were nailed and on these, corrugated galvanised iron sheets 2400mm x 900mm were secured by means of drive-screws all round their edges. All timbers had been previously treated with creosote forced in at a pressure of 170 lbs per square inch.

Roughly each hectare covered took: 5928 rafters, 1112 purlins, 1161 piles; 5928 sheets, 2920 kgs of screws and 850 kgs of washers.

Catchment

The collecting channels were designed to convey a maximum of 102 mm of rain per hour on an area of about 14.97 hectares (this being the area available for eventual conversion into catchments). The access footpaths along the channels were incorporated in the design to act as a relief channel fed by an overflow system and itself overflowing through pipes down to sea. The main channel in the east west tunnel has a valve via which water can be diverted into a natural fissure and eventually down to the sea. Water from the first rains, which washes the dirt from the catchments, is flushed away in this manner. The catchments and channels ceased operations as a water source in October 1993.

Reservoirs

Between 1911 and 1914 reservoir No 5, of 9,091 cubic metres capacity, was excavated from the rock by means of enlarging a tunnel driven parallel to the channel tunnel and some 7.6 metres below it. The tunnel was enlarged on either side to form a chamber some 12.2 metres high 13.1 metres wide and 121.9 metres in length. After the excavation works were completed and all loose rocks removed, the floor was concreted in two layers, a 150 mm levelling layer of mass concrete followed by a 150 mm slab of 1:2:4 concrete using Portland cement and 35mm stone as coarse aggregate. The walls were constructed using two skins each of 114 mm space between the back wall and the rock face was filled with mass concrete and the 150 mm cavity filled with a Portland cement, 1:1 mortar mixed with 5% water proofing agent. The floor received a 50 mm Portland cement, 1:1 mortar screed and finally rendered with a 19 mm layer containing 5% of water proofing agent. The walls were cement plastered in 3 coats using a 3:1, 2:1 and 1:1 with 5% water proofing agent mix. The last layer of wall plaster and floor render was steel trowelled. Nothing was done to the roof as the rock over the span used is self-supporting.

The catchment area was increased by a further 5.66 hectares and, in 1928, a further reservoir (No 6) was constructed similar to reservoir No 5, but of half its length and with a capacity of 4,545 cubic metres. Each reservoir is connected to the main channel by means of large diameter pipes with valves to control the entry of water into them. They are now also connected to the pumping mains conveying water from other sources. Between 1928 and 1945 four more reservoirs (Nos 7 to 10) were excavated from the rock adding a further 18,181 cubic metres to the storage capacity. It is interesting to note that reservoir No 10, which had been excavated but not completed at the time of World War II, contained a barracks built to house a detachment of the “Black Watch” regiment under bombproof conditions. The construction of these reservoirs follow the original pattern except that they are offset from the pilot tunnel thus providing access to their supply mains. Outlet valves for supply and cleansing are operated from within the reservoirs by means of long spindled hand wheels.

Each reservoir has an overflow onto the pilot tunnel and via the tunnel into the natural fissure. The last reservoirs (Nos 11 and 12) were constructed 1958-1961 at a lower level, reached from the east side, opposite Catalan Bay. These were constructed to receive rain from a further extension of 4.05 hectares of catchment at a lower level on the east side slopes. These brought up the total number of potable water reservoirs to 12 plus the Moorish Castle reservoir providing a total storage capacity of some 72,727 cubic metres. Following the ceasing of operations, of the catchments as a source of potable water in October 1993 the reservoirs are used as service reservoirs and as storage reservoirs providing substantial water reserves.

Importation

When all the water resources proved inadequate in the past either due to a long dry season or poor rainfall during the wet season, water was imported by means of tankers usually on their maiden voyage and carrying some 22,000 cubic metres of potable water, usually from the United Kingdom.

Wells

In 1933 further investigations and exploration were carried out at the isthmus. This demonstrated that there were two aquifers; an upper unconfined one of fresh water and a lower confined one of brackish water. Development of the upper aquifer was then carried out. The water from the wells was conveyed to a tank at Hesses Pumping Station from where it is pumped up to the Waterworks to be blended with desalinated water. The water derived from these wells was high in chloride content and had a high degree of hardness. Water obstruction from the wells ceased being operationally viable following the construction of the new air port terminal 2011.

Distillation

The first distillation used for the production of water was in 1956 when a vapour compression distiller was constructed at Hesses Pumping Station. This plant produced distilled water, which was blended with the well water to produce a water of more acceptable quality. The plant was not very successful. In 1964 a small 182 cubic metres per day vertical tube multi stage flash distiller was installed at Kings Bastion Electricity Generating Station and used waste heat from the generators’ diesel engines. The water so produced was pumped to the blending tank at Hesses and from there to the Waterworks. The plant came to the end of its useful working life in 1976.

In 1969 a 909 cubic metres per day long tube multi stage flash distiller was commissioned. The plant was situated opposite the North Face, at Devils Tower Road, with its sea water intake at Eastern Beach. This plant pumped water direct to Waterworks. The plant came to the end of its working life in 1984.

In 1973 a vertical tube evaporator using enhanced heat transfer tubes designed by the United Kingdom Atomic Energy Authority was installed on reclaimed land at the North Mole. The water from this plant was pumped to Hesses blending tank and from there to Waterworks. The plant came to the end of its operational life in 1984.

Present Plant

The present two multi-stage flash distillers at Waterport were commissioned in 1984. These plants are each rated at 1,350 cubic metres per day and are able to use waste heat from the electricity generators, at the Waterport Generating Station. In 1991 the desalination plant complex at Waterport was expanded to include two Reverse Osmosis Desalination plants each rated at 2400 cubic metres per day. These plants were decommissioned in 2011.

An Agreement was entered into by GOG, in 1990, for the construction of a refuse incinerator that was to produce steam from waste heat and in turn 650,000 cubic metres a year of potable water via three distillation plants. The incinerator is no longer functioning.

In 2001 two 1000 cubic metres per day Reverse Osmosis plants were purchased by AquaGib Ltd. and are fully operational.

In 2001 two 1,000 cubic metres per day reverse osmosis plants were purchased by AquaGib Ltd from Uniflo Services UK and installed at Governors Cottage Camp next to the refuse incinerator site. Use was made of the existing raw water and product water infrastructure built for the then ex incinerator plant. In 2008 two extra 1,200 cubic metres per day reverse osmosis plants were purchased by AquaGib Ltd and installed at Governors Cottage Camp. At the same time the two existing plant’s membranes were upgraded and production increased to 1200m³ .This increased the daily production capacity of the four plant at the Governors Cottage Camp to 4,400 cubic metres per day.

An extra reverse Osmosis Plant of 1,500m³ was purchased by AquaGib Ltd from Kirton Engineering Ltd and installed at Waterport, at the old desalination site at North Mole making use of the existing raw water pumping station and product water forwarding system to Waterworks.

This increased the production capacity of AquaGib Ltd to a maximum of 6,300m³.